Services

What We Do

- I.G.A (Investment Grade Audit) Full site analysis, Calculated Savings Based on ASHRAE 19.17 & 18.30, Key Coded Mock-Ups, 3D Rendering (Windows and Thermal Walls only)

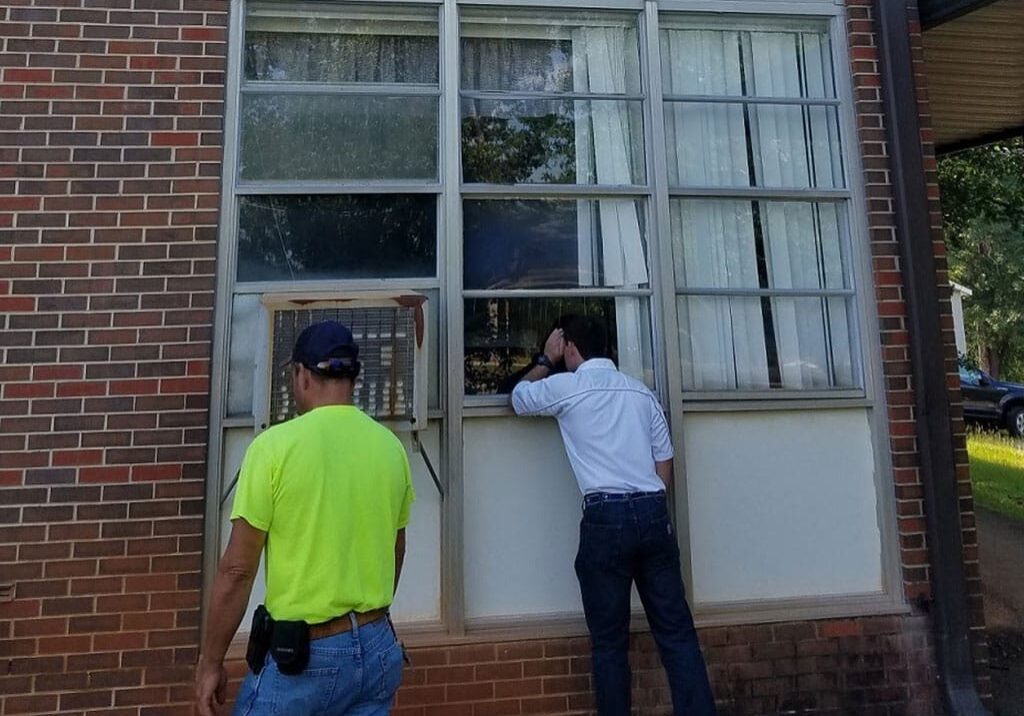

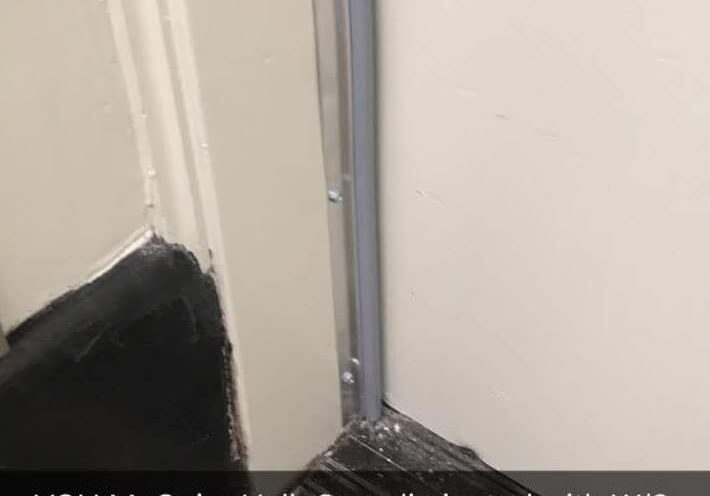

- Weatherization (sealants, weather-stripping,vapor and thermal barriers)

- Window & Door replacement

- Polyurethane Roof Systems

- Thermal Wall Systems

- High Performance Coating Systems [Elastomeric]

- Building Improvements [Painting, Power-Washing, Mold and Asbestos Remediation

Why We Do It

Air Sealing: What it is and why it is important

Solution Overview

Air infiltration (also referred to as leakage) is the uncontrolled and unintentional flow of unconditioned outside air through gaps, cracks, and small openings in the building envelope. This air leakage places an extra burden on the building’s heating and cooling systems, resulting in increased utility costs. Infiltration is typically an unnoticed source of energy loss that compounds over time as building envelope components fail due to misuse, age, settling, or poor workmanship. By filling in cracks and tightening the building envelope, these loads can be significantly reduced, improving energy efficiency and occupant comfort. Most importantly, these measures reduce humidity infiltration into the space, improving the learning environment while reducing energy consumption.

Energy Conservation Opportunities

Building envelope is a critical element of a sustainable building; however, it is often overlooked when prioritizing energy and capital funding. As buildings age, building envelope materials expand and contract over time, creating gaps which can make a big impact on energy efficiency. Air infiltration through these gaps permits untreated outside air to enter the building, which results in drafts, excess humidity, and increased energy consumption. Particular areas of interest for building envelope improvements include weather-stripping on doors, caulking around windows, sealing intersections between walls and roof components, and sealing around mechanical penetrations for ventilation and exhaust systems.

Impact

The following highlights the key benefits of this solution:

- Reduce Energy Costs – Reduced infiltration and air leakage can result in reducing the burden on HVAC systems by 25% to as much as 40%.

- Improve Occupant Comfort and the Learning Environment – Minimizing drafts of untreated air, noise, and infiltration of moisture improves occupant comfort and productivity levels.

- Improve Building Pressurization – Air sealing helps maintain proper air balance and minimizes the stack effect created by vertical air leakage paths.

- Improve Indoor Air Quality – A tighter building envelope reduces infiltration of outdoor air pollutants, dust, radon, paths for insect infestation, and infiltration of moisture.

Benefits of Improvement(s)

The benefits of a comprehensive envelope improvement project are increased thermal comfort and decreased energy consumption garnered through a reduction in unwanted air infiltration through the perimeter wall.

Increased thermal comfort. Drafts will be reduced providing greater comfort for the building occupants. Decreased energy consumption. Less conditioned air will be lost through the building envelope and the Heating Equipment will not have to work as hard to maintain the set point of the conditioned space, which will decrease the energy consumed and save on steam energy costs.

The more complete the integrity of the physical structure, the more efficiently the HVAC system will operate and as originally designed. All areas of the building were surveyed that would allow for energy loss through the “Building Envelope”. There are three methods for heat transfer: 1) conduction, 2) convection and 3) radiation.

Calculation of Energy Savings

The energy savings derived from this measure are a result of the heating and cooling systems (chillers and boilers) not having to work as hard to achieve the desired environmental conditions. The amount of savings is dependent on the existing building conditions and the amount of air leakage under the current operating conditions.

Energy savings are based on the ASHRAE crack method calculations. If the process reveals any variation in the as-built conditions, then savings will be adjusted accordingly. Determination of air current air leakage rates is based on many factors, including:

- Linear feet of cracks

- Square feet of openings

- Stack coefficient

- Shield class

- Average wind speed

- Heating or cooling set point

- Average seasonal ambient temperatures

Energy Savings Projections - Overall Approach

Energy savings are calculated using a monthly degree day method (ASHRAE Handbook of Fundamentals 2013 19.17 & 18.30). Monthly degree days are calculated as follows over each month; HDD = (1 day) ∑ (T b - T out ) + and CDD = (1 day) ∑ (T out - T b ) +